Reduced weight loss and controlled ripening: these are the advantages of cheese ripening packaging. Whether hard cheese, semi-soft or firm semi-hard cheese – allfo’s various packaging solutions allow the products to mature to the perfect cheese flavour. The packaging specialist produces customised multilayer films in the form of e.g. side-gusseted bags, loose bags and chain bags for optimised cheese ripening. Thanks to a film structure that is customised to the product, allfo achieves a precisely defined gas permeability that allows the escape of ripening gases and at the same time prevents the penetration of oxygen.

“Film ripening is the economical alternative to traditional cheese rind ripening and an important component in industrial cheese production. To ensure an optimised process, we rely on product-oriented advice and an individual film structure. This enables us to achieve an intelligent gas exchange that optimally supports the maturing of the cheese in the film,” explains Johannes Bach, Sales Export Director at allfo GmbH & Co. KG. The special film allows ripening gases to escape, but at the same time prevents oxygen from entering.

Multiple benefits for cheese ripening

Thanks to the intelligent gas exchange, allfo’s cheese ripening packaging offers multiple benefits for dairies and cheese dairies: maturing in the film makes the process easier to control and the quality of the cheese reproducible. In addition, film ripening leads to less weight loss in the cheese than is the case with the conventional method. As the cheese does not form a rind during film ripening, no salt treatment is required. “All of this significantly reduces storage and maintenance costs for dairies and cheese dairies,” emphasises Johannes Bach.

The packaging solutions from allfo preserve the aroma and flavour of the cheese during the maturing process and beyond. They also ensure a longer shelf life for the cheese and offer optimum product protection against oxygen, moisture and microorganisms. The cheese ripening packaging, whether as a loose bag, side-gusseted bag or chain bag, scores highly in terms of puncture resistance and, when used correctly, prevents so-called air pullers. These occur when air penetrates the packaging and impairs the ripening process of the cheese, which can lead to undesirable changes in flavour and texture and even mould formation.

From film to bag

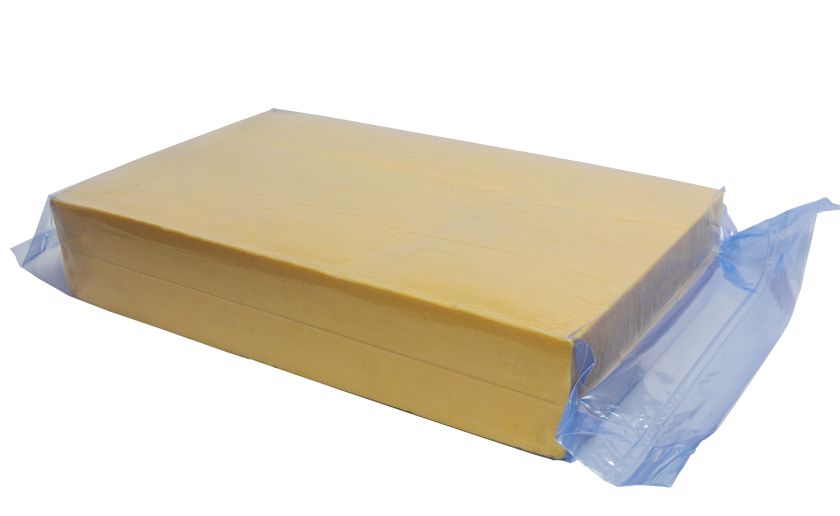

The basis for allfo’s cheese maturing bags are customised multilayer films, which are manufactured on state-of-the-art extrusion lines specifically according to product and customer requirements. The packaging specialist offers its customers these PA/PE films, optionally with an EVOH barrier, on rolls. allfo also processes the films into a wide range of packaging solutions: loose bags such as tubular and sealed-edge bags or side-gusseted bags can be used to pack sliced and hard cheeses as well as cheese blocks or round loaves and adapt perfectly to the shape of the cheese to be packaged. Chain bags are the solution for the automatic packaging process.

For even more customisation, the films for cheese ripening can also be produced in different colours and individually printed with up to ten colours using flexographic printing.

Photo: allfo