The Fraunhofer Institute for Process Engineering and Packaging IVV will be attending the parts2clean 2023 trade fair taking place in Stuttgart from Sept 26 to 2. The company will be showcasing two pioneering technology solutions which address the cross-industry challenges posed by stricter energy efficiency and climate protection targets, increasing cleanliness requirements and the shortage of skilled workers.

To meet the challenges of manual cleaning processes, Fraunhofer IVV has developed a sensor-based cleaning lance that, for the first time, guarantees a reliable, recordable and reproducible cleaning process, even for manual spray-based cleaning. ‘CleanAssist’ systematically records each cleaning step and ensures precise and efficient cleaning management, facilitating compliance with audit guidelines as well as standardised training.

The fully integrated sensor technology in the cleaning lance automatically captures the cleaning performance and all relevant process parameters. Surfaces that have been cleaned are documented and sensitive areas, such as sensitive components, can be blocked for cleaning if necessary.

A basic requirement for quality-assured, needs-based cleaning processes and efficient quality management is the ability to reliably detect the current surface contamination level.

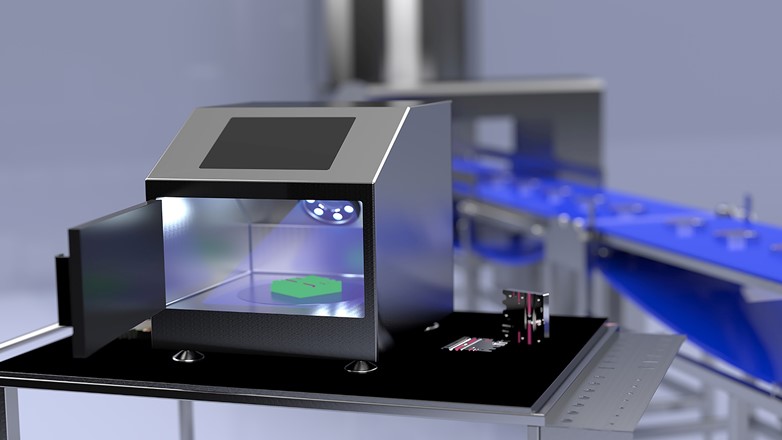

To allow reproducible, fast and complete detection of contamination, Fraunhofer IVV has developed the ‘CoControl-Lumi3D’ optical detection system. The system only needs a few seconds to determine filmic impurities based on the fluorescence response of organic substances. ‘CoControl-Lumi3D’ also enables automated, traceable documentation of the contamination level.

While conventional systems only capture filmic impurities on a one- or two-dimensional level, ‘CoControl-Lumi3D’ is able to assign the detected contamination to a position in space. Linking the 3D model of the component to the gathered information allows users to selectively check functional surfaces, such as seals or joints, for compliance with the required cleanliness criteria.

The measuring system can be customised to clean room level and can be used both directly in production as an inline application or as an at line or offline solution in the laboratory. For more visit hall 10, booth D28 or fraunhofer.de