Five, eight, ten billion predicted by 2050 – the world’s population is constantly growing and so is the demand for food. To meet this need, traditional agriculture is reaching its ethical and ecological limits. Food producers need to think and act in new ways. Precision fermentation is playing a key role in this transformation. In this process, selected or ‘reprogrammed’ microorganisms produce high-quality food ingredients as a kind of biological mini-factory.

Fermentation has accompanied mankind since early times. Beer, wine, sourdough and kimchi are just a few examples. In principle, fermentation involves enzymes or microorganisms producing one or more new substances from a starting substrate. For example, fermentation of sugar in beer production produces alcohol. Precision fermentation now goes one step further: through selection or genetic reprogramming, microorganisms in an intelligent bioreactor can produce a variety of food ingredients such as proteins, vitamins, enzymes, aromas, pigments and fats. It is already possible to produce cheese from milk proteins that have never been in contact with a cow. This is an interesting process, and not just in terms of the ecological footprint: The Boston Consulting Group and impact investor Blue Horizon expect alternative proteins alone to generate sales of 290 billion US dollars along the value chain by 2035.

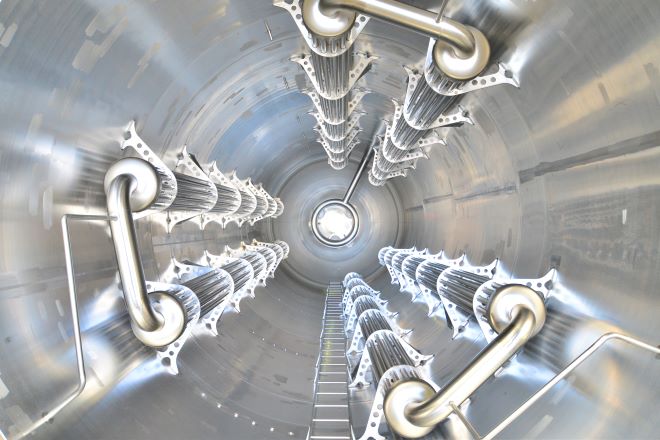

The most important component of precision fermentation in terms of process technology is the bioreactor. On the one hand, it must be able to precisely implement the very individual process parameters of the organisms, such as substrate supply, temperature, aeration or the use of an agitator. In addition, remarkably high demands are placed on its hygienic design and cleanability. These are all challenges that Ziemann Holvrieka GmbH meets without reservation thanks to its more than 170 years of experience in the design and production of high-quality tanks and process solutions for the global beverage and liquid food industry.

For example, the HACCP specifications and recommendations of the European Hygienic Engineering & Design Group (EHEDG) are implemented consistently and down to the last detail right from the design stage. With the state-of-the-art electric polishing systems, roughness depths of less than 0.3 μm can be achieved. A riboflavin test is also carried out before delivery to ensure that the surfaces can be cleaned efficiently and without leaving any residue.

The design of a bioreactor is always based on the customer’s individual framework conditions. This high level of flexibility also applies when plant designers select units for cooling or heating processes, valves and pumps, implement international specifications or take into account local conditions such as the risk of earthquakes or high wind loads. At this stage, the Finite Element Analysis (FEA) tool is used for stress and safety calculations, and the future process can already be simulated using additional Computational Fluid Dynamics (CFD). For more visit ziemann-holvrieka.com