Arla Foods Kruså has replaced its microfiltration system with a UV pasteurisation system from Lyras, a Danish company specialising in sustainable pasteurisation technology, to minimise the environmental impact of its salad cheese production.

Waste and energy consumption has been reduced, while cleaning and operational processes have also become simpler and cheaper. As a result, Lyras’ UV technology, known as Raslysation, will be Arla Food Kruså’s chosen method of brine treatment for the company’s production of salad cheese.

Said Vagn Clausen, Packaging Manager, Arla Foods Kruså: “Our new UV system from Lyras enables us to reuse 100% of our brine and thereby eliminate the CO2 emitted from the salt retentate disposal. Additionally, we have reduced our energy and water consumption which is a significant step forward for our overall carbon footprint. From microfiltration, 10-12% of the salt is disposed of as retentate.

“Cleaning has also become cheaper and easier, taking just 15 minutes. The solution is also considerably cheaper compared to cleaning microfiltration systems. Importantly, the working environment for our employees has also improved, and Lyras’ Raslysation system has ensured that the high quality of our product is maintained, if not exceeding our previous output.

” It’s great that traditional technology is being challenged by new innovations. Technology like Raslysation could well be the future of our industry, as the technology is incredibly simple. It makes our job easier and helps protect the environment.”

Added Claus Werner Fischbach, Process Operator, Arla Foods Kruså: “It’s much easier to operate the new UV system from Lyras compared to the microfiltration plant we had used previously. We control the Raslysation unit from our SCADA system, just as we do with the rest of our process equipment. The Lyras system worked from day one and we’re pleased with the results.”

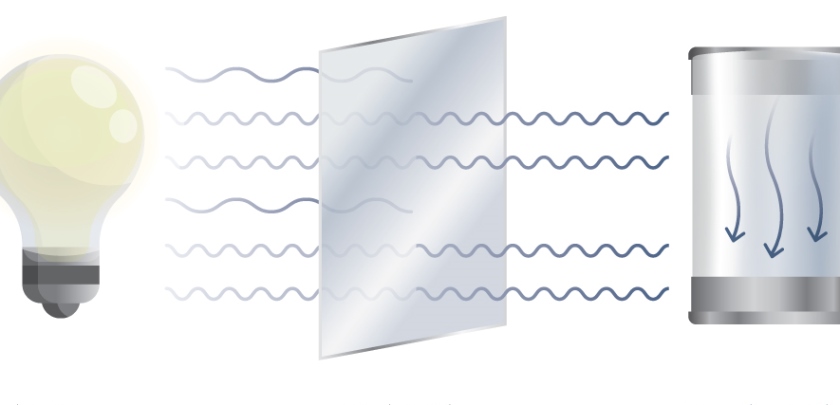

Raslysation is a non-thermal treatment that uses UV light at a specific wavelength to pasteurise opaque liquid food and non-food products, including dairy, juice and enzymes. The liquid is directed past the light source in a controlled movement so that everything is illuminated to inactivate bacteria and other microorganisms. For more visit lyras.com