Functional, clear and multifaceted: Schubert customers now have everything under control with the new customer portal. At the interpack 2023 and for the very first time, Schubert’s service division will be presenting how companies can best use and benefit from the portal, from purchasing to production to maintenance. The Digital CARE Services for analysing machine data are also integrated on the platform.

As an innovation driver in the industry, Schubert not only takes care of the technical maintenance of machines with its 4YOU Services, it also ensures comprehensive services for its customers throughout the entire machine lifecycle and along all processes. The packaging machine manufacturer has now integrated its Digital 4YOU CARE Services (Connection for Analytics, Reporting and Efficiency) for the analysis and targeted evaluation of machine data into a new customer portal, which was presented for the first time at interpack 2023.

The background to the open-system portal is a collaboration among several manufacturers to create a comprehensive digital industry platform for the food, luxury food and cosmetics industries. With the standardised solution, machine builders and product manufacturing companies can easily network with each other for preventive maintenance, monitoring and asset management, and optimise their project management.

Detailed information on lines and projects

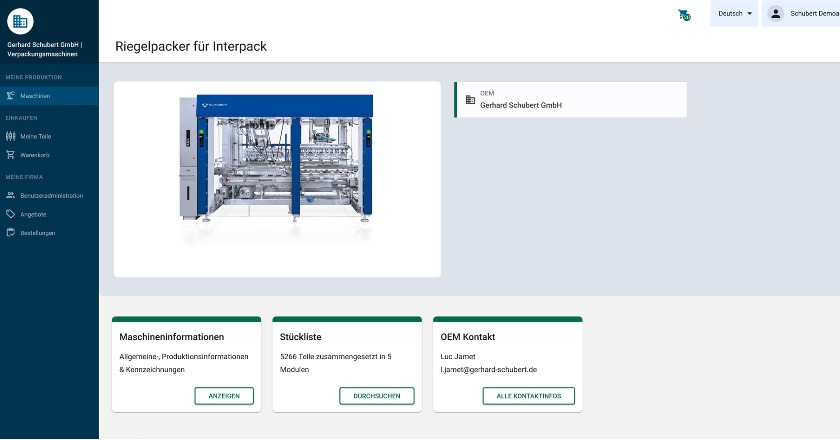

The clearly designed interface offers direct access to different areas, for example production with the machines and lines of the respective manufacturers, the purchase of parts and services, your own company data and the Digital CARE Services for the Schubert machines. Particular importance was paid to a user-friendly and clear presentation in menu navigation. At the same time, extensive and detailed information can be stored in the portal, for example technical data sheets, operator manuals, notes on spare parts, orders, invoices and the like. The customer portal offers three different ways to identify spare parts, from searching for part numbers to parts lists and 3D visualisations. The comprehensive information makes the new customer portal an extremely useful platform and first point of contact for many industry professionals, from purchasing to fault analysis or to organising modifications. For example, spare parts can be searched for and immediately ordered in the portal, technical specifications of machines can be queried, maintenance intervals can be planned, or deliveries and invoices can be checked.

Integrated: The Digital CARE Services

Digital data is a vital currency in the packaging process, which is why Schubert has integrated its Digital CARE Services into the customer portal. Uwe Galm, Director Customer Services at Schubert, explains: “Targeted data analyses help prevent unplanned downtimes, reduce rejects and increase productivity. All in all, this results in more efficiency, more sustainability and greater competitiveness for our customers in the long run.”

In this portal area specifically for Schubert customers, detailed analyses of production and machine data can be called up, providing a precise overview of production output, performance, rejects, top ten faults and more. For example, production management, maintenance or purchasing can all work with the portal and quickly deal with typical day-to-day situations and challenges with the help of the customer portal’s various functions. “In conclusion,” says Uwe Galm, “the customer portal provides answers to a variety of questions, from live production data to spare parts orders, and is therefore an incredibly valuable support in day-to-day production.”