IDM ¦ Technology/IT

8 · February 2020 ¦ international-dairy.com

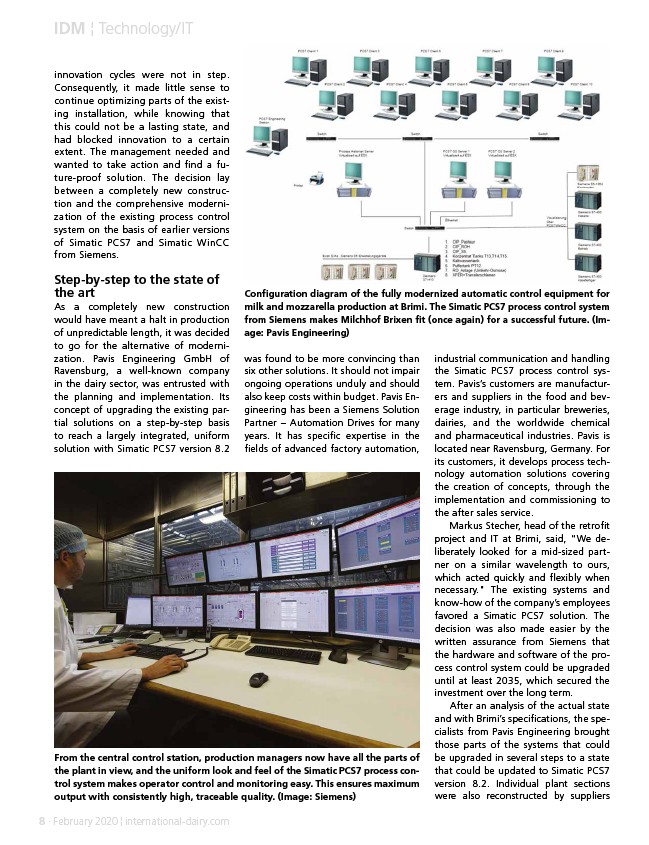

Configuration diagram of the fully modernized automatic control equipment for

milk and mozzarella production at Brimi. The Simatic PCS7 process control system

from Siemens makes Milchhof Brixen fit (once again) for a successful future. (Image:

Pavis Engineering)

innovation cycles were not in step.

Consequently, it made little sense to

continue optimizing parts of the existing

installation, while knowing that

this could not be a lasting state, and

had blocked innovation to a certain

extent. The management needed and

wanted to take action and find a future

proof solution. The decision lay

between a completely new construction

and the comprehensive modernization

of the existing process control

system on the basis of earlier versions

of Simatic PCS7 and Simatic WinCC

from Siemens.

Step-by-step to the state of

the art

As a completely new construction

would have meant a halt in production

of unpredictable length, it was decided

to go for the alternative of modernization.

Pavis Engineering GmbH of

Ravensburg, a well-known company

in the dairy sector, was entrusted with

the planning and implementation. Its

concept of upgrading the existing partial

solutions on a step-by-step basis

to reach a largely integrated, uniform

solution with Simatic PCS7 version 8.2

was found to be more convincing than

six other solutions. It should not impair

ongoing operations unduly and should

also keep costs within budget. Pavis Engineering

has been a Siemens Solution

Partner – Automation Drives for many

years. It has specific expertise in the

fields of advanced factory automation,

From the central control station, production managers now have all the parts of

the plant in view, and the uniform look and feel of the Simatic PCS7 process control

system makes operator control and monitoring easy. This ensures maximum

output with consistently high, traceable quality. (Image: Siemens)

industrial communication and handling

the Simatic PCS7 process control system.

Pavis’s customers are manufacturers

and suppliers in the food and beverage

industry, in particular breweries,

dairies, and the worldwide chemical

and pharmaceutical industries. Pavis is

located near Ravensburg, Germany. For

its customers, it develops process technology

automation solutions covering

the creation of concepts, through the

implementation and commissioning to

the after sales service.

Markus Stecher, head of the retrofit

project and IT at Brimi, said, "We deliberately

looked for a mid-sized partner

on a similar wavelength to ours,

which acted quickly and flexibly when

necessary." The existing systems and

know-how of the company’s employees

favored a Simatic PCS7 solution. The

decision was also made easier by the

written assurance from Siemens that

the hardware and software of the process

control system could be upgraded

until at least 2035, which secured the

investment over the long term.

After an analysis of the actual state

and with Brimi’s specifications, the specialists

from Pavis Engineering brought

those parts of the systems that could

be upgraded in several steps to a state

that could be updated to Simatic PCS7

version 8.2. Individual plant sections

were also reconstructed by suppliers