News ¦ IDM

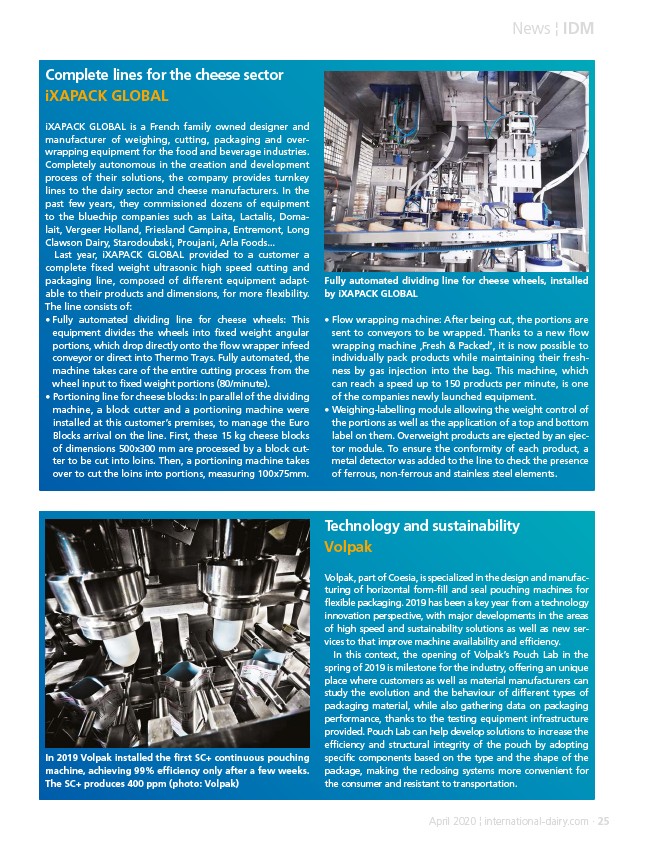

Fully automated dividing line for cheese wheels, installed

by iXAPACK GLOBAL

Technology and sustainability

Volpak

April 2020 ¦ international-dairy.com · 25

Complete lines for the cheese sector

iXAPACK GLOBAL

Volpak, part of Coesia, is specialized in the design and manufacturing

of horizontal form-fill and seal pouching machines for

flexible packaging. 2019 has been a key year from a technology

innovation perspective, with major developments in the areas

of high speed and sustainability solutions as well as new services

to that improve machine availability and efficiency.

In this context, the opening of Volpak’s Pouch Lab in the

spring of 2019 is milestone for the industry, offering an unique

place where customers as well as material manufacturers can

study the evolution and the behaviour of different types of

packaging material, while also gathering data on packaging

performance, thanks to the testing equipment infrastructure

provided. Pouch Lab can help develop solutions to increase the

efficiency and structural integrity of the pouch by adopting

specific components based on the type and the shape of the

package, making the reclosing systems more convenient for

the consumer and resistant to transportation.

iXAPACK GLOBAL is a French family owned designer and

manufacturer of weighing, cutting, packaging and overwrapping

equipment for the food and beverage industries.

Completely autonomous in the creation and development

process of their solutions, the company provides turnkey

lines to the dairy sector and cheese manufacturers. In the

past few years, they commissioned dozens of equipment

to the bluechip companies such as Laita, Lactalis, Domalait,

Vergeer Holland, Friesland Campina, Entremont, Long

Clawson Dairy, Starodoubski, Proujani, Arla Foods...

Last year, iXAPACK GLOBAL provided to a customer a

complete fixed weight ultrasonic high speed cutting and

packaging line, composed of different equipment adaptable

to their products and dimensions, for more flexibility.

The line consists of:

• Fully automated dividing line for cheese wheels: This

equipment divides the wheels into fixed weight angular

portions, which drop directly onto the flow wrapper infeed

conveyor or direct into Thermo Trays. Fully automated, the

machine takes care of the entire cutting process from the

wheel input to fixed weight portions (80/minute).

• Portioning line for cheese blocks: In parallel of the dividing

machine, a block cutter and a portioning machine were

installed at this customer’s premises, to manage the Euro

Blocks arrival on the line. First, these 15 kg cheese blocks

of dimensions 500x300 mm are processed by a block cutter

to be cut into loins. Then, a portioning machine takes

over to cut the loins into portions, measuring 100x75mm.

• Flow wrapping machine: After being cut, the portions are

sent to conveyors to be wrapped. Thanks to a new flow

wrapping machine ‚Fresh & Packed‘, it is now possible to

individually pack products while maintaining their freshness

by gas injection into the bag. This machine, which

can reach a speed up to 150 products per minute, is one

of the companies newly launched equipment.

• Weighing-labelling module allowing the weight control of

the portions as well as the application of a top and bottom

label on them. Overweight products are ejected by an ejector

module. To ensure the conformity of each product, a

metal detector was added to the line to check the presence

of ferrous, non-ferrous and stainless steel elements.

In 2019 Volpak installed the first SC+ continuous pouching

machine, achieving 99% efficiency only after a few weeks.

The SC+ produces 400 ppm (photo: Volpak)